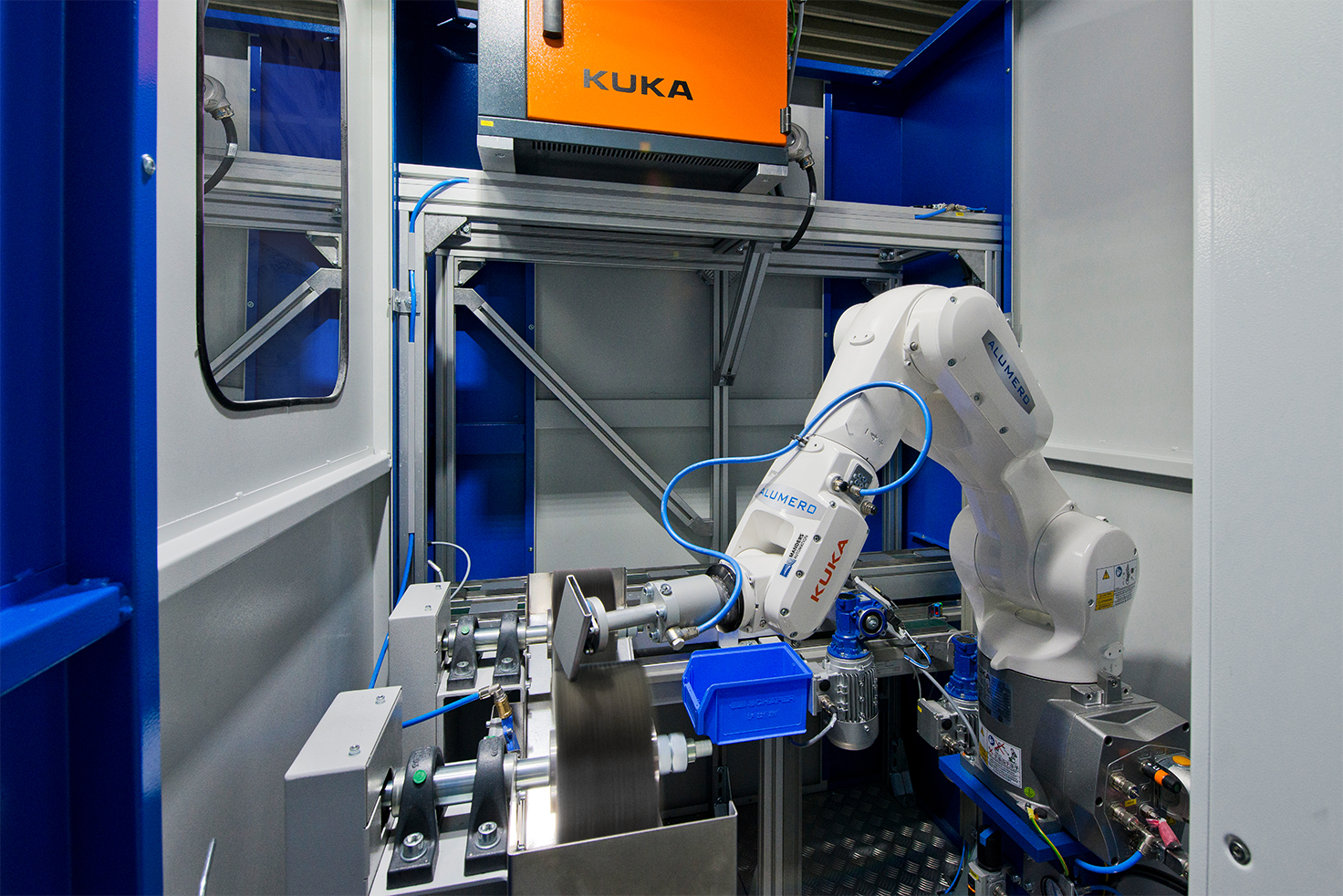

ALUMERO FINEX Extrusions from Helmond came to us with an important issue regarding the production process of high-quality pocketware products to be produced on a large scale. To set up the production process more efficiently and to ensure quality, our knowledge and specialty was called upon to assemble a deburring cell with KUKA robots.

About ALUMERO FINEX Extrusions

The Helmond-based family business ALUMERO FINEX Extrusions B.V. is part of the Austrian Alumero Group. With more than 25 years of experience, Alumero is a specialist in the aluminum market. Here, FINEX is focused on specific aluminum precision of microprofiles with minimum tolerances and thin wall thicknesses.

At FINEX, they do not believe in standard solutions but like to work with short lines and do not use minimum order quantities. Every customer has its own requirements and custom solutions are always worked out for and, above all, with the customer. Quality and service are far more important to FINEX than quantity.

The market in which FINEX specializes cannot be straightforwardly defined. The parent company currently divides its activities into the categories Solar, Living, Industry, Bautec and Extrusion. For each category, the Alumero Group is totally unburdening its customers from the initial idea to the complete finished product. This is no different with FINEX and its specialization.

Quality and progressive pocketware

One of ALUMERO FINEX Extrusions B.V.’s customers is Secrid. A Dutch company focused on developing pocketware and distinctive card holders and wallets. This company has a decorative product with a unique Dutch-Made, A-Product market positioning and a highly connected supply chain. For this customer, it is incredibly important that the aluminum end profiles are fully sized and uniquely and highly deburred. The demand for pocketware is increasing and due to the fact that this is an A-brand, maintaining quality is extremely important. Regardless of volume reduction. To guarantee the same high quality at a higher volume, ALUMERO FINEX Extrusions B.V. decided to automate production.

Our expertise was soon called upon to come up with an innovative solution to optimize the process. Therefore, a demand arose for a specialized sawing machine and connecting deburring cells with KUKA robots. These deburring cells contain a KR6 R900 AGILUS robot on which a suction cup is mounted. The robot operates at various speeds at different defined angles and starting points. The great advantage of the KUKA robot is that it was programmed by ALUMERO FINEX Extrusions B.V. and Manders Automation in such a way that adjustments per profile and per robot cell are possible to meet the different customer needs.

The sawing machine cuts the aluminum profile to the desired dimensions and, via a conveyor belt, this profile is then placed in the robotic cell. The robot then picks up that profile and ensures that both the inside and outside contours are carefully finished. After this, the robot again places the profile on the conveyor belt that takes the profiles to the next stop.

This production automation was necessary because ALUMERO FINEX Extrusions B.V. always goes to great lengths to meet its customers’ needs. Thanks to automation, it is now able to increase its production capacity without sacrificing quality. On the contrary, because every product produced is now guaranteed to be of the same high quality due to automation. In addition, the automation offers added value by collecting data and thus creating synergy with the basic extrusion.

An important requirement from our client was that the automation should absolutely not be detrimental to the personnel who are also active in production. So the machines also had to provide a pleasant working environment. The employees who used to be responsible for the repetitive production of the profiles are now operators of the robots. Indeed, the robots generate a lot of data that give the close-knit team feedback on production processes.

This synergy is extremely important for ALUMERO FINEX Extrusions B.V.. The KUKA robots and the employees must be able to work together perfectly, so that production runs optimally and there is always room for improvement. Because we have made the entire automation process as flexible as possible and ALUMERO FINEX Extrusions B.V. has retrained its workers on the shop floor to work with this flexibility, it can guarantee quality even when customer requirements change.

The extra step

For this assignment, we also went beyond the current problem and looked together into the future. The entire automation process is designed so that ALUMERO FINEX Extrusions B.V. can further expand its automation step by step in the future. For example, in the area of visual technical aluminum surface control, there are still numerous possibilities and all options are also open for the entire process after extrusion.

So it was also immediately clear to ALUMERO FINEX Extrusions B.V. that we were the best partner for this first part of the automation project. We understood the challenge right away. People and robots must form a synergy, they must work together in order to achieve the best result. The solution we worked out in combination with our training and service offerings gave the customer great confidence. Furthermore, ALUMERO FINEX Extrusions B.V. is also still very positive about their first experience with KUKA robots and the quality from a R&D trajectory. For companies without any knowledge of robots, KUKA robots are very user-friendly and it is easy to learn how to operate them. This was certainly important for the personnel who need to be retrained for this purpose.

Qualitative cooperation between humans and robots was an important requirement for us in this automation project. Because of this investment, we started outsourcing and co-creation in the field of automation. The involvement of our personnel, the service of Manders Automation and KUKA and training were important elements in this.

Need a partner who goes the extra mile?

Do you have an important issue related to the production process and are you looking for innovative and scalable solutions to meet your customer’s demand and high quality requirements? Then contact us without obligation to discuss the possibilities.