Handling

We provide a handling solution that fits seamlessly into your production process.

The best handling process for your production

Handling is always an important part of our automatic assembly and joining solutions. But even as an individual technique, handling can do a lot to improve your production process.

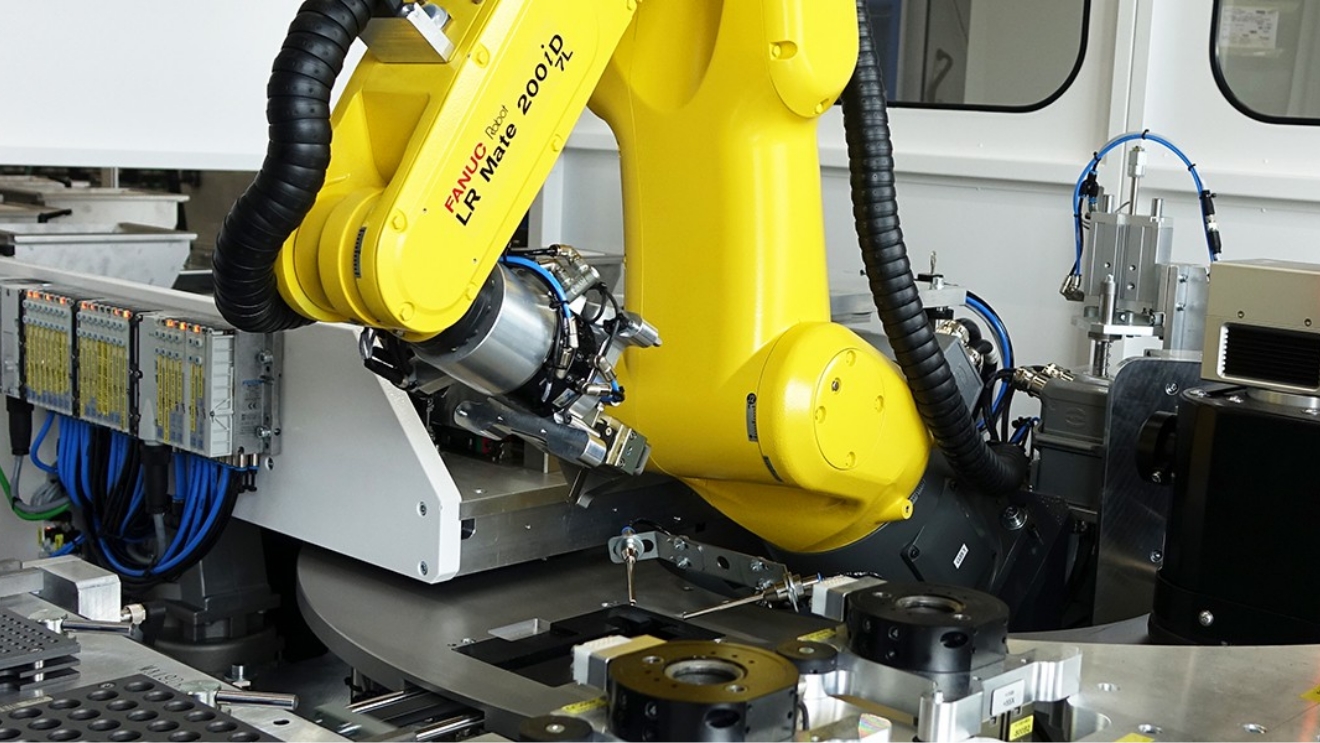

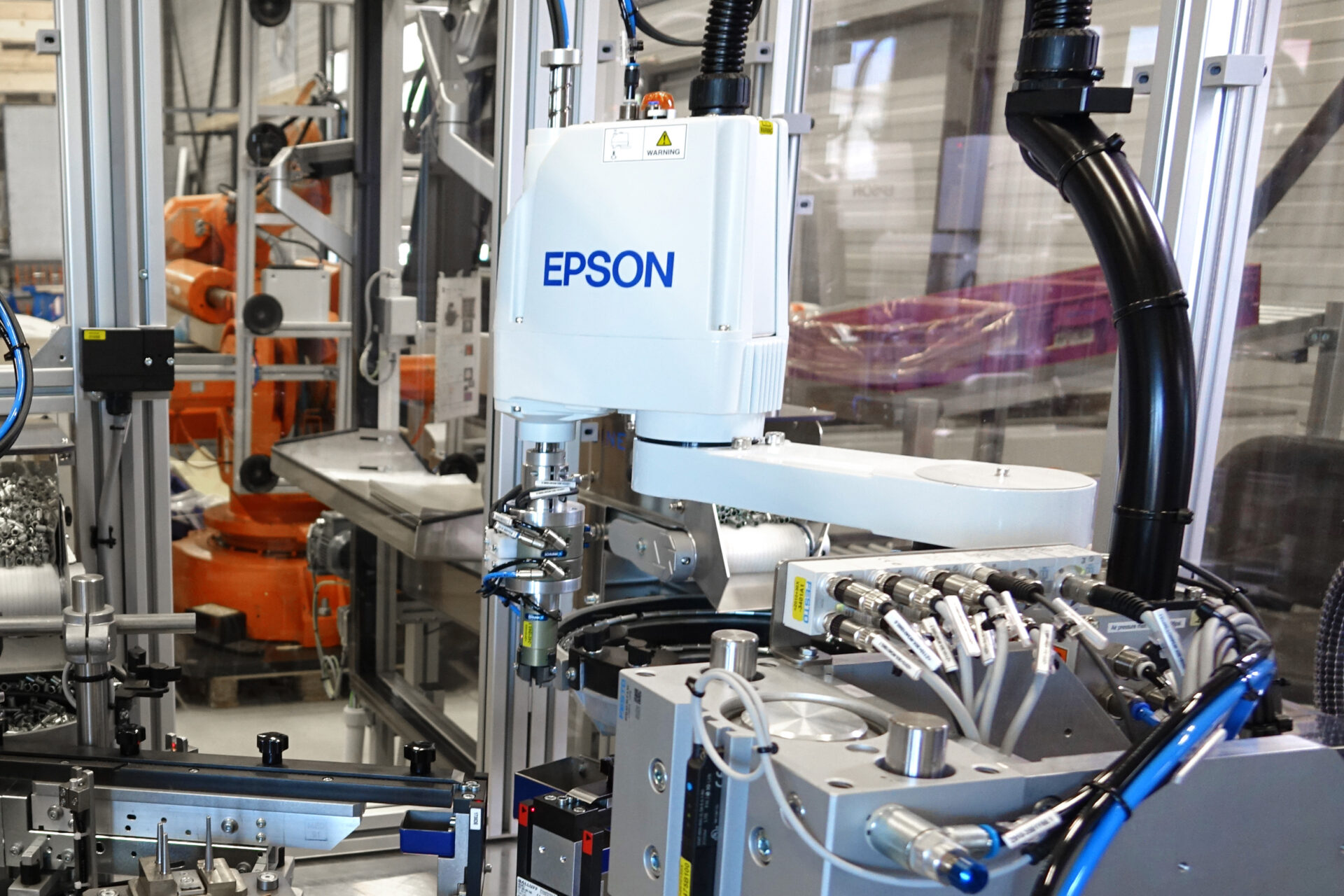

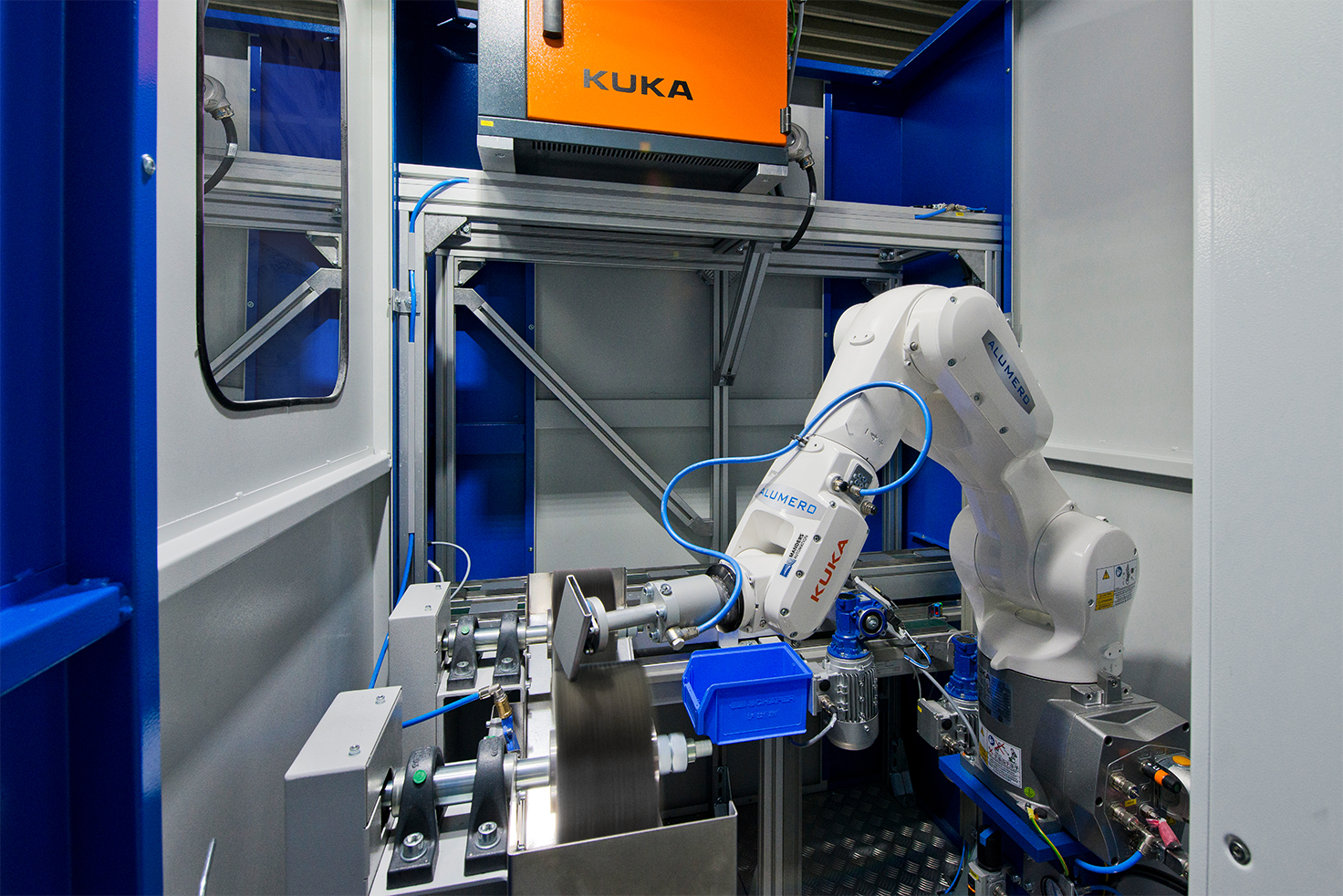

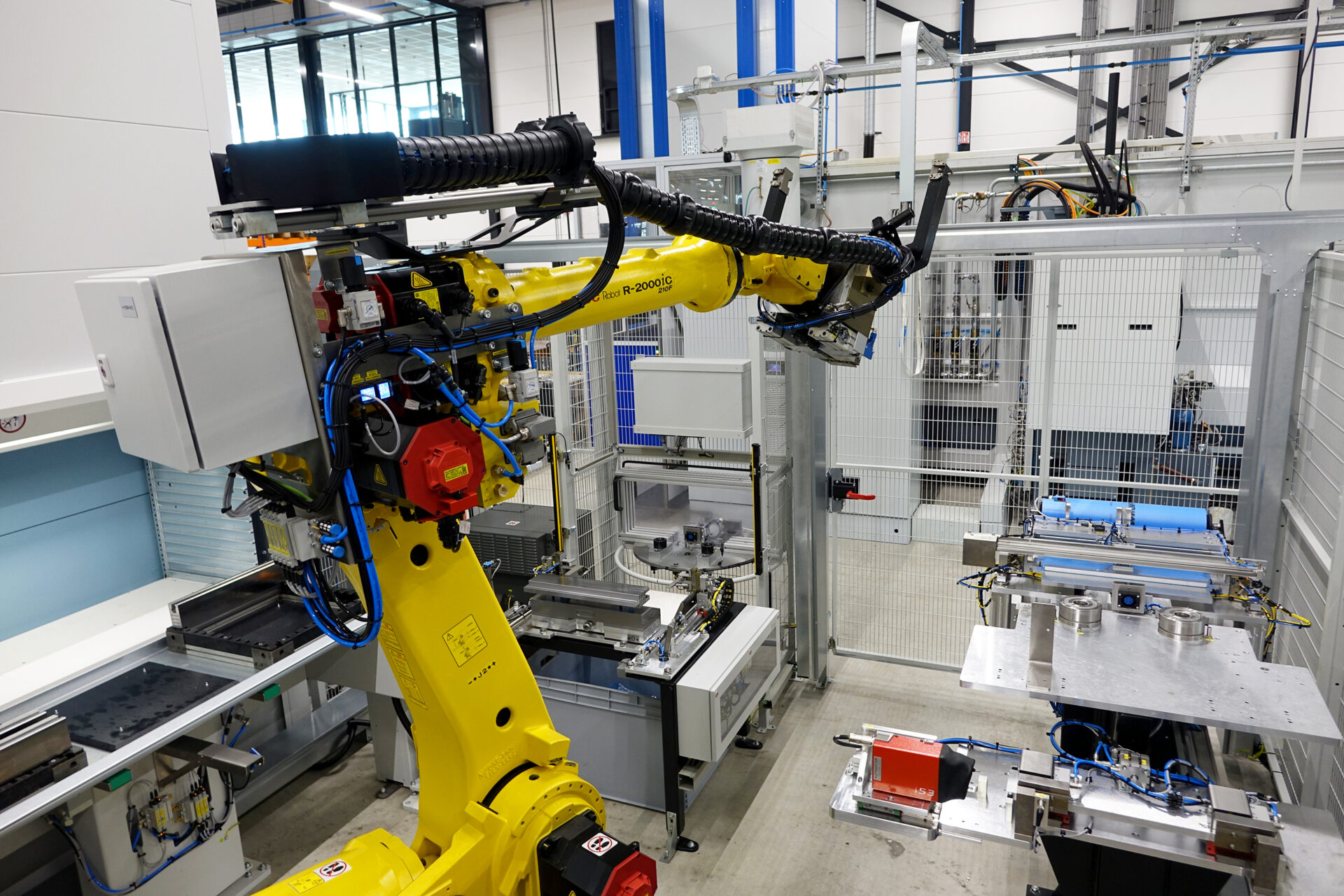

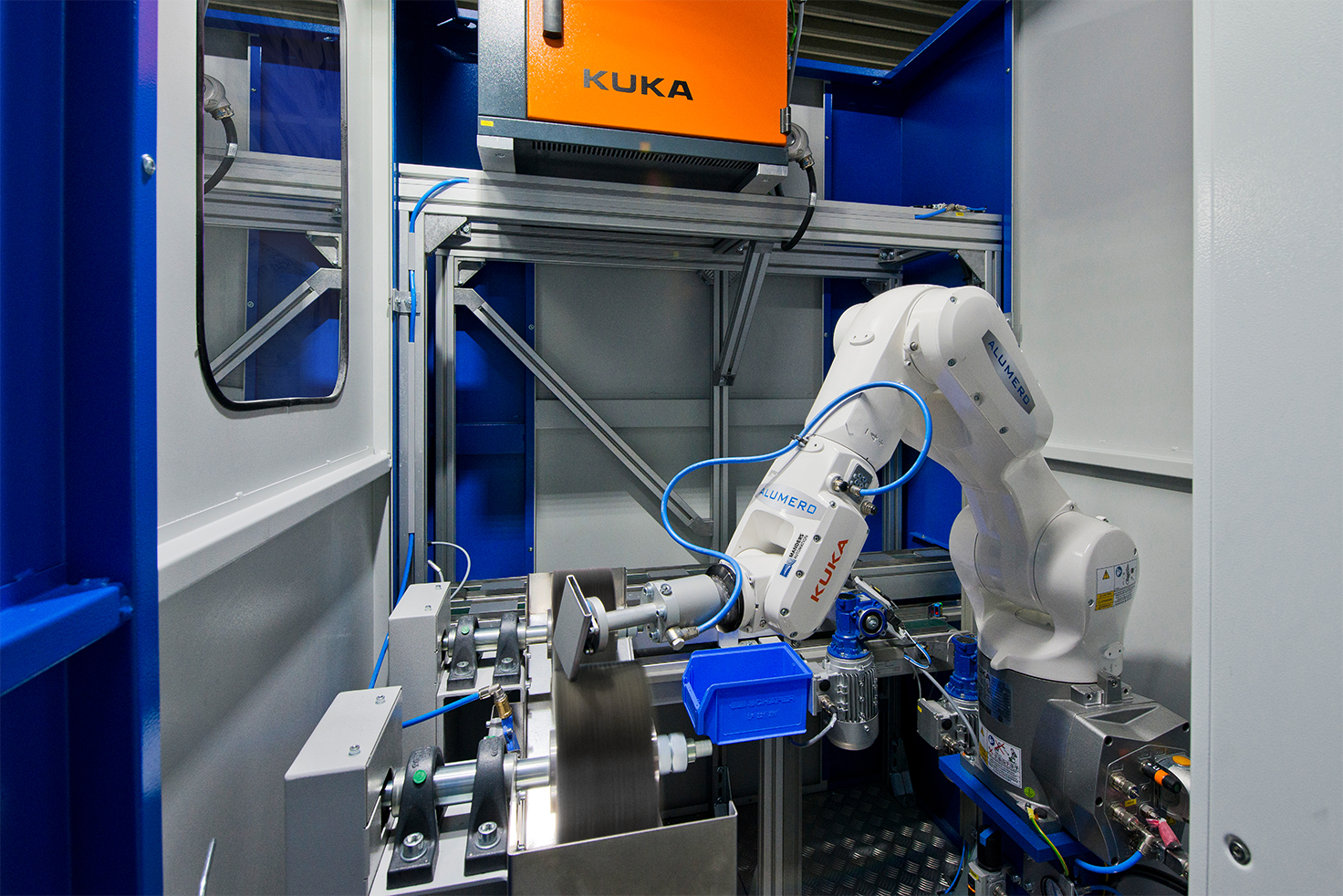

Handling with robots

Handling without robots

Room for growth

Benefits of automation

More efficient production

Reduce your cycle times and increase production without extra staff

Improving quality

Rely on consistent product quality with fewer human errors

Increase security

Provide a safe and ergonomic working environment for your employees

Reducing costs

Improve your production with reduced personnel and rejection costs

Projects

Each production process is unique. Take a look at our previous assembly projects.

Customised

No standard solution

Almost every process can be improved by automation, including automatic handling. But a concrete tile requires a different handling process than a syringe. We therefore do not make standard solutions, but first look at what you need. Based on your product, vision of the future and the available budget, we design and build a machine that fits your process perfectly.

Frequently asked questions

We get these questions about automated handling more often

We understand that you have many questions at the start of an automation project. That is why we have answered the questions we have heard most often over the past 40 years. Would you like us to think about your project or do you have other questions first? Please feel free to contact us.

If it is important for you to be able to collaborate with the robot, a collaborative robot can indeed be a godsend. But in doing so, don’t forget that you also need to take safety measures with cobots. Would you like advice on this? We are happy to think along with you about what is the best solution for your process.

Of course, this depends entirely on what you need and what your requirements are in this respect. In doing so, we are immediately honest about the payback period and do not try to sell you a machine if we do not see a business case for it.

Our software colleagues can programme robots from Fanuc, ABB, Kuka, Yaskawa, Mitsubishi and Epson for you. We are happy to advise which robot is most suitable for your process.

Depending on your current process and the solution we may create for you, you can count on higher production output, better and more consistent quality, a better working environment for your employees and lower production costs.

Customers