Welding Technologies

With our experience and attention to detail, we integrate welding processes into automated solutions where quality and safety are of utmost importance. We ensure optimal protection against sparks and fumes, cooling of electrodes and fixtures, and the maintenance of tolerances.

Resistance Welding

We build and test our machines in-house, offering a solution that meets your specific requirements and needs. We create various solutions for:

- Spot Welding

- Projection Welding

- Capacitor Discharge Welding

In addition to our custom-built machines, we also offer standard machines that can be customized based on your preferences.

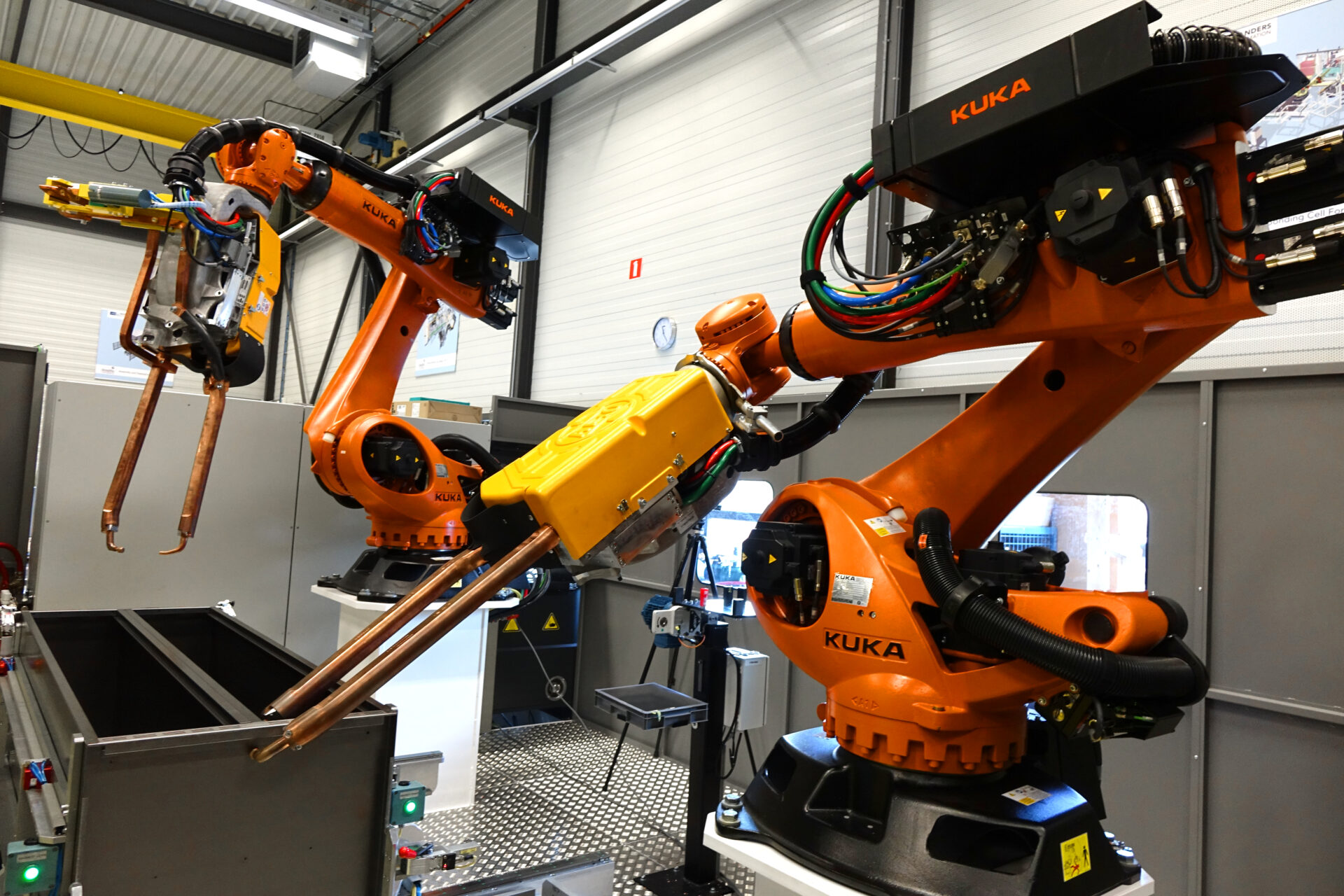

Spot Welding

In addition to standard spot welding processes, we also offer the possibility of using combined joining techniques. This solution is highly demanded in industries like automotive. In this process, a line is added to the connection, making it stronger. What makes it unique is that we can combine these two processes with a robot in a cell.

Need more output that a single welding gun can’t provide? You can apply multiple welding cylinders that work on the product simultaneously. This is an efficiency improvement that reduces operator production and waiting times, thus lowering your production costs.

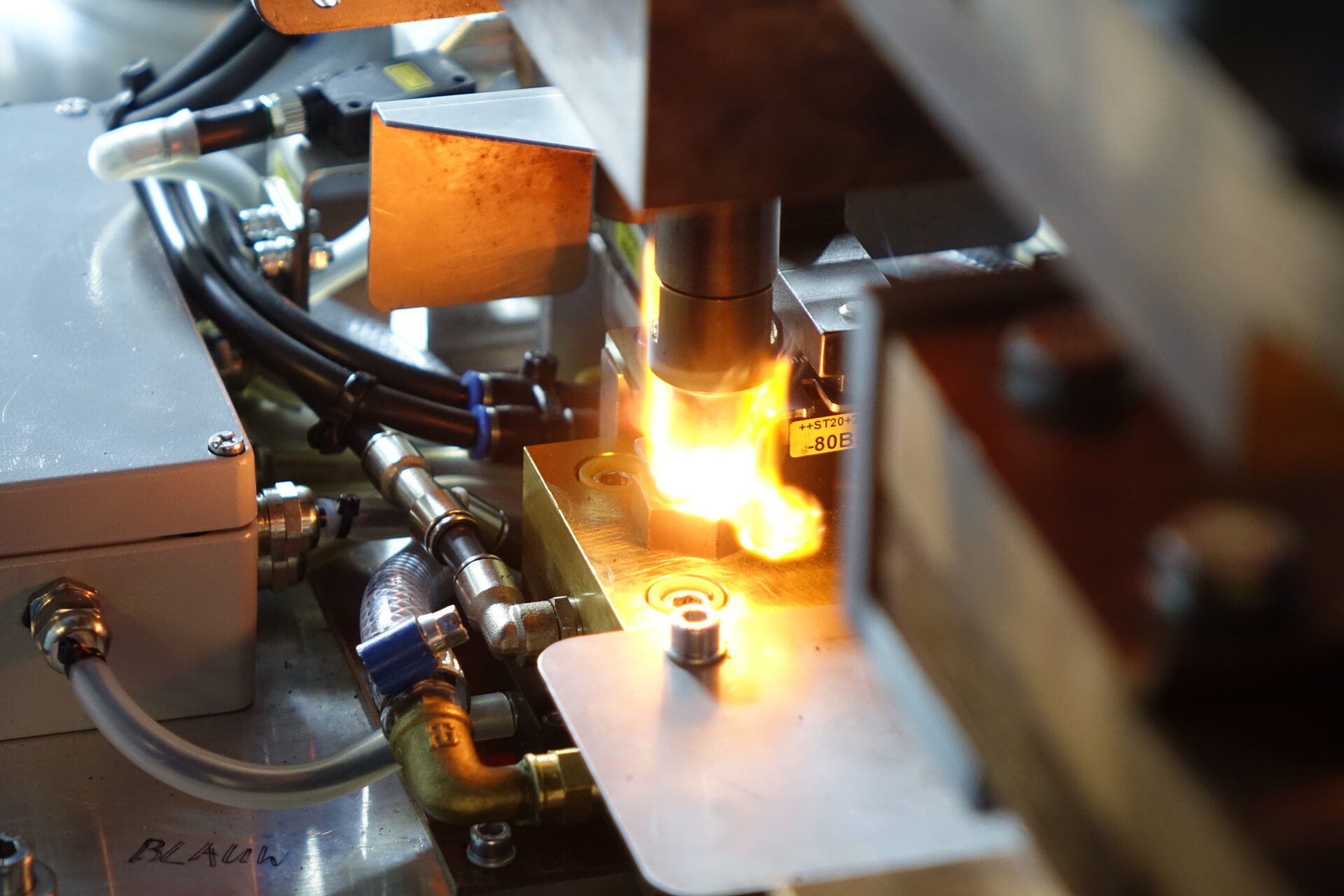

Projection Welding

When more force is required, we offer innovative solutions in projection welding. We can achieve a welding force of more than 4,000 kg by combining multiple cylinders with an electrode. Projection welding can be used with or without fasteners, and our machines have the advantage of using various feed solutions, making the machine versatile and improving the efficiency of the production process.

We can also apply multiple detection and control systems to ensure that the orientation of the projection is always 100%.

In our innovative solutions, we place the welding cylinder upside down, so the electrodes are reloaded when the product is moved. This significantly shortens the production process and saves you costs. If you need multiple fasteners on a product, we offer multi-head welding rods that can weld up to four different fasteners onto a product.

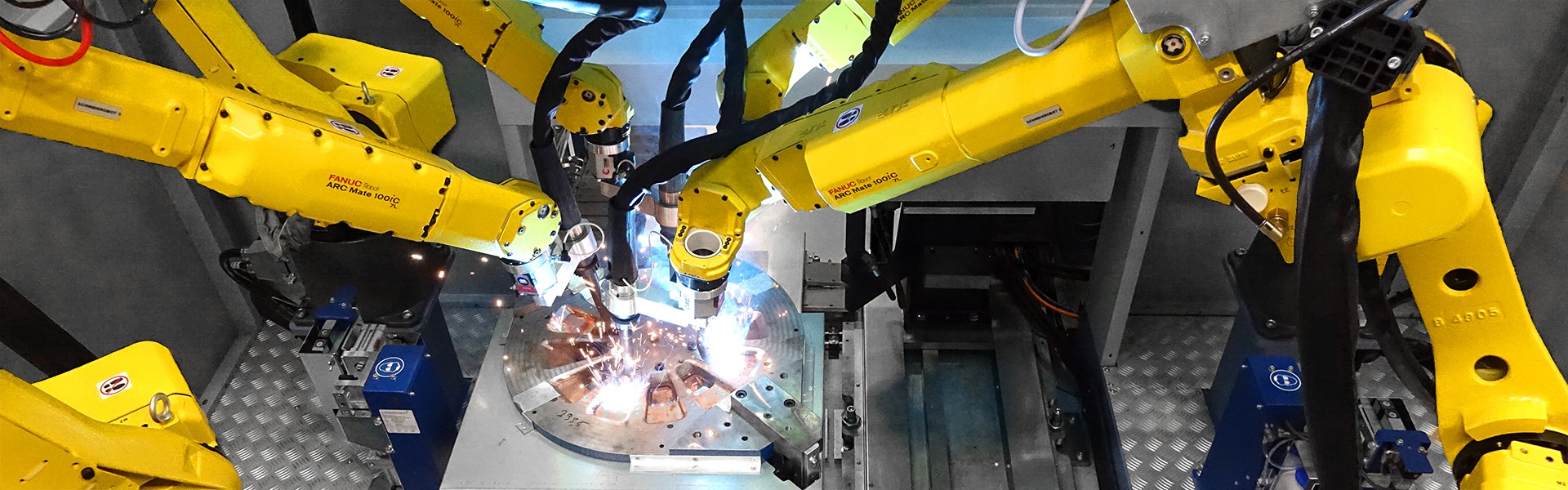

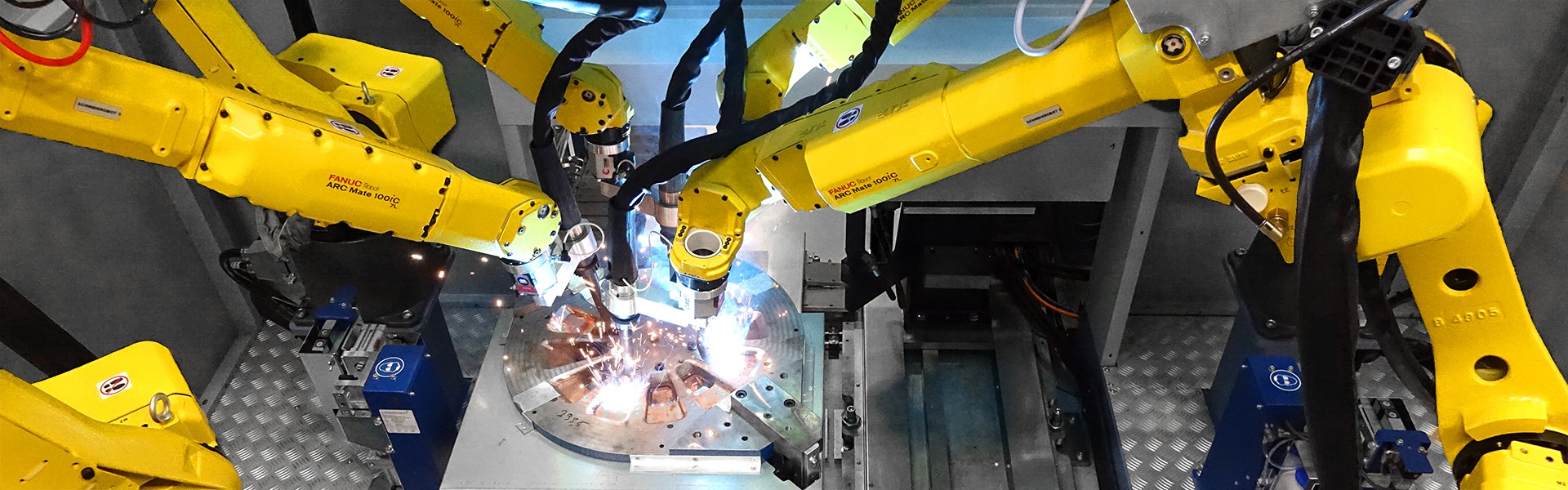

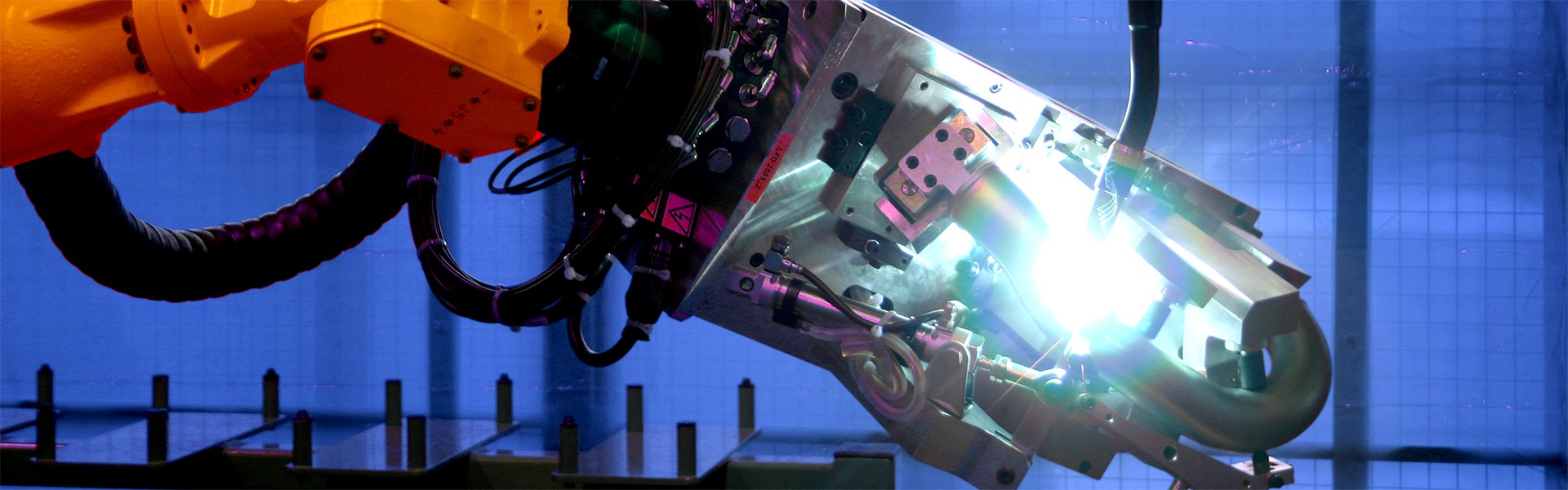

Arc Welding

We integrate the following types of arc welding techniques into our machines:

- MIG/MAG Welding

- TIG Welding

- Plasma Welding

We create specific welding jigs for your products, ensuring that products are welded correctly and that you can easily add new products to existing welding processes.

Laser Welding

For welding metals and non-conductive materials, such as plastics and glass, we offer machines capable of making narrow welds at high speeds with extreme precision. Thanks to the small spot size and the high energy density of the laser beam, energy is precisely applied to the material being welded.

Other Applications

Looking for another welding solution not mentioned above? We are always interested in innovations and the latest techniques that we can apply. Feel free to contact us to discuss your production process and the requirements for your project.