ADAPTIX

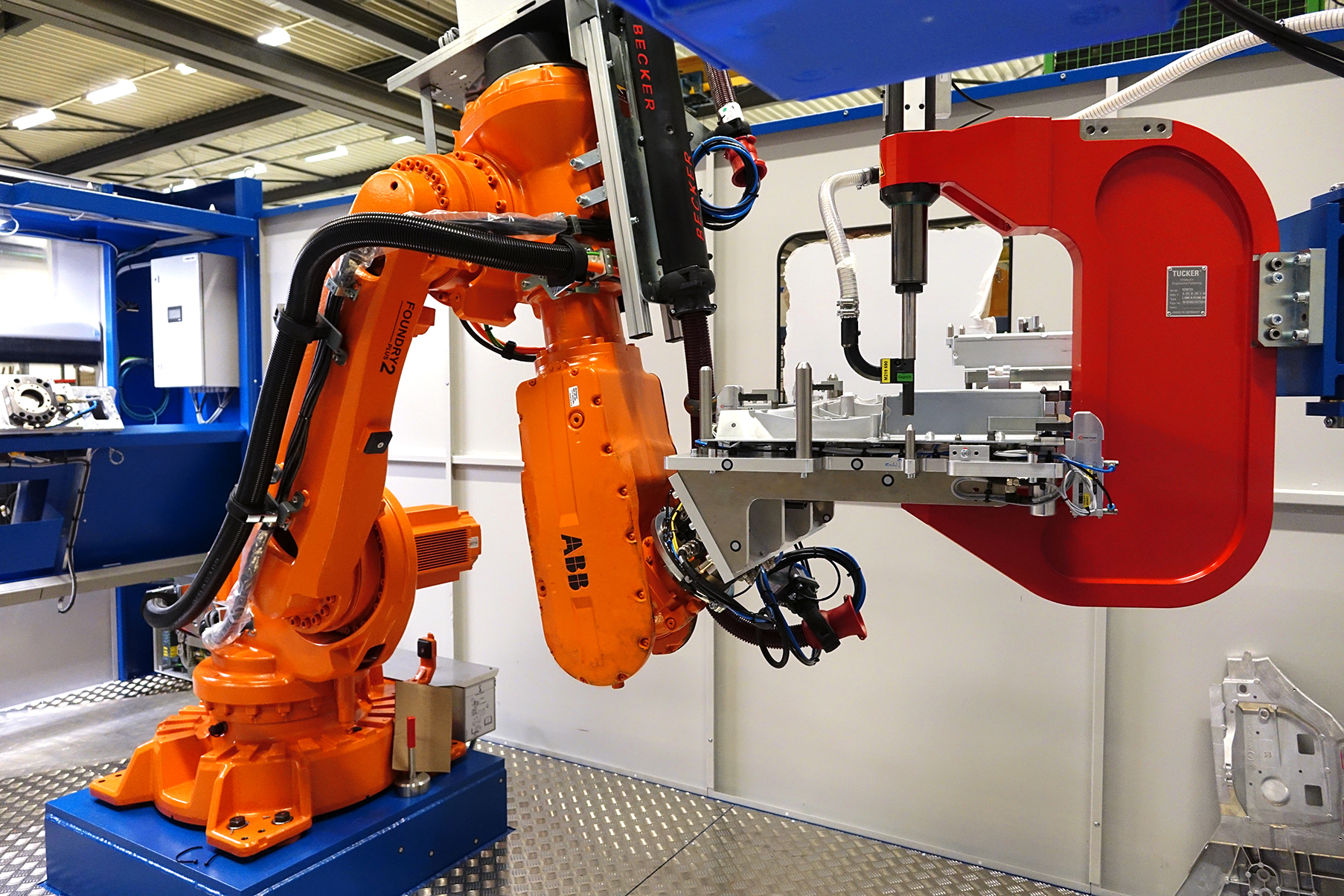

One modular solution that flexibly combines products and processes

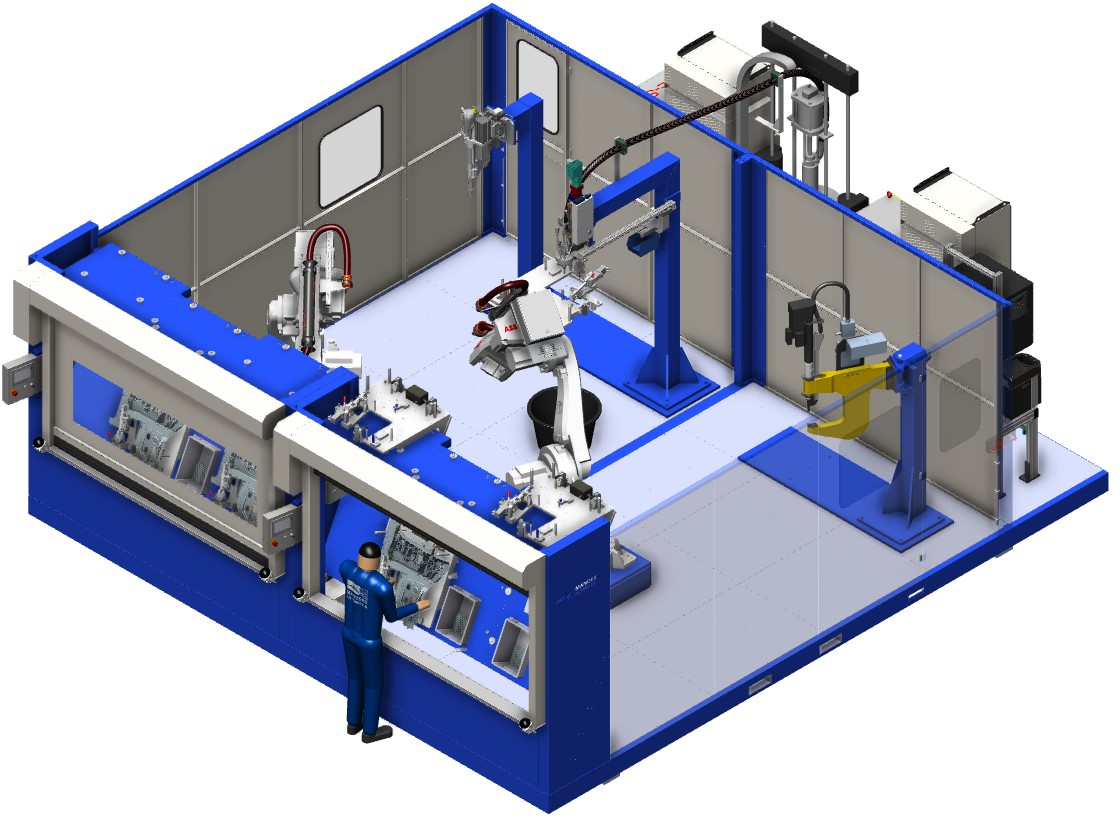

About ADAPTIX

Moving quickly and flexibly is no longer a bonus, but a prerequisite for success. Just like the need to reduce costs and maximize efficiency.

That’s why we created ADAPTIX: a modular solution that combines various automated joining techniques. Extremely flexible, future-proof and above all: cost-effective. With ADAPTIX you are ready for the next step in your process in one go.

Therefore ADAPTIX

The advantages of this modular solution

Extremely flexibel

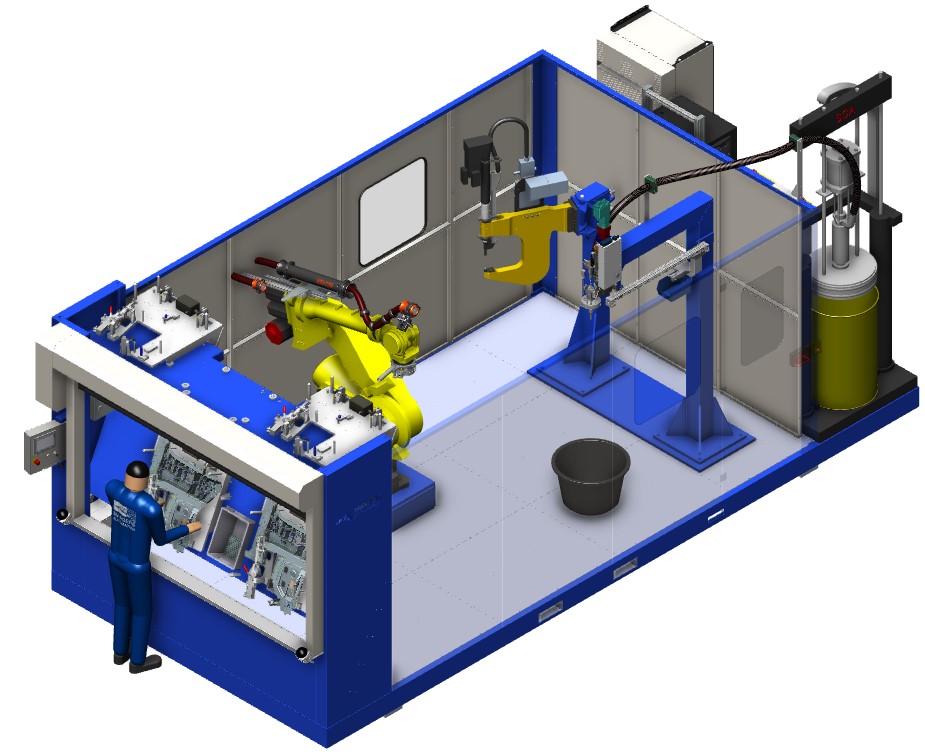

Thanks to the modular construction and the availability of various ‘building blocks’ you can both reuse and expand your ADAPTIX. The lifespan is also significantly increased by the stationary setup.

Cost-effective

The flexibility also ensures lower investments per product and cost-effective production of new products. Certainly in small series. In addition, an ADAPTIX cell does not require a reinforced foundation and is extremely compact. This allows you to make optimum use of the space on your production floor.

Lightning fast

ADAPTIX speeds up your production process by bringing the product to the process. In addition, we can install the cell within three days, as we will already have extensively tested it on our site with your product and operators.

Intelligent

The ADAPTIX system is easy to connect to external ICT systems for order management and quality monitoring. This means that the cell not only fits seamlessly into your production process, but is also integrated with all important data systems.

User friendly

An ADAPTIX cell requires minimal interaction and no advanced knowledge is required for operation. In addition, the design is very user-friendly so that the operator can perform their work in an ergonomically pleasant way.

Reliable

ADAPTIX is hardly susceptible to malfunctions. But if something unexpectedly goes wrong, you can count on our expert support: wherever and whenever. Via remote access we can look directly into the cell and our field service engineer is ready to provide support on location.

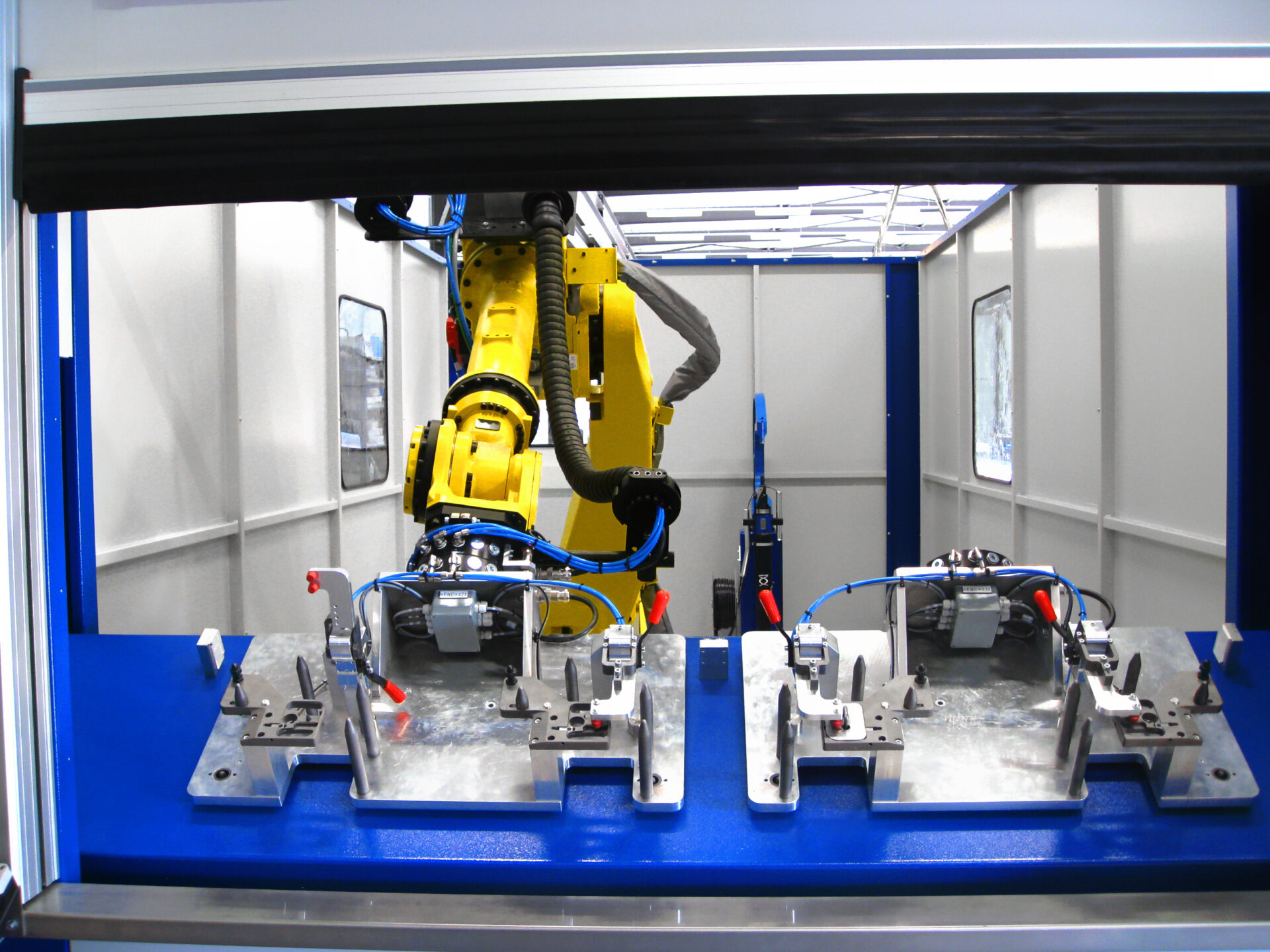

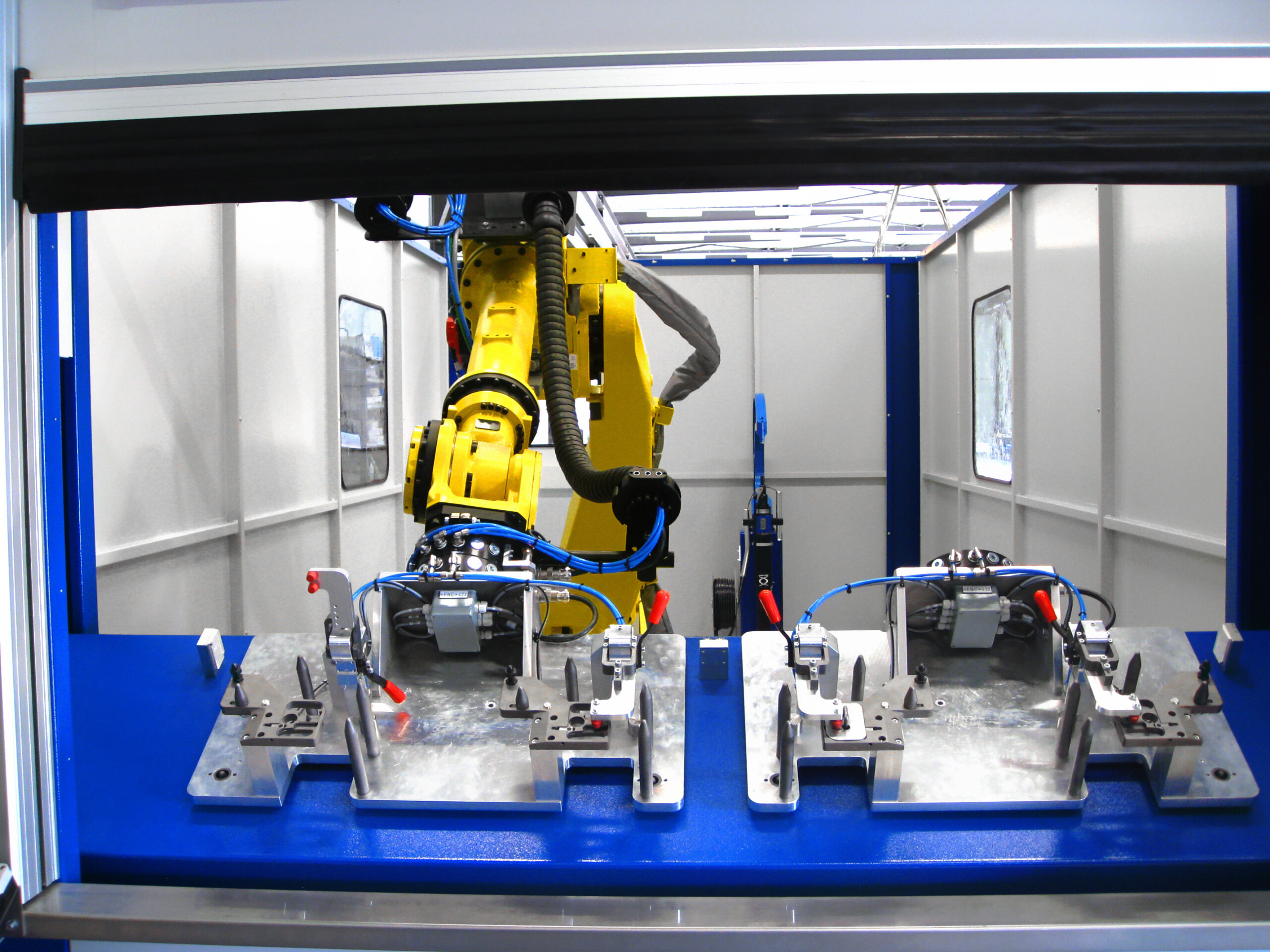

Configuration cases

Examples of ADAPTIX set-ups

Curious about how ADAPTIX fits into your process?

Let’s plan a meeting in which we focus completely on your specific production process. You’ll quickly know whether this concept is suitable for your site and what the possibilities are.