Precision and efficiency in one

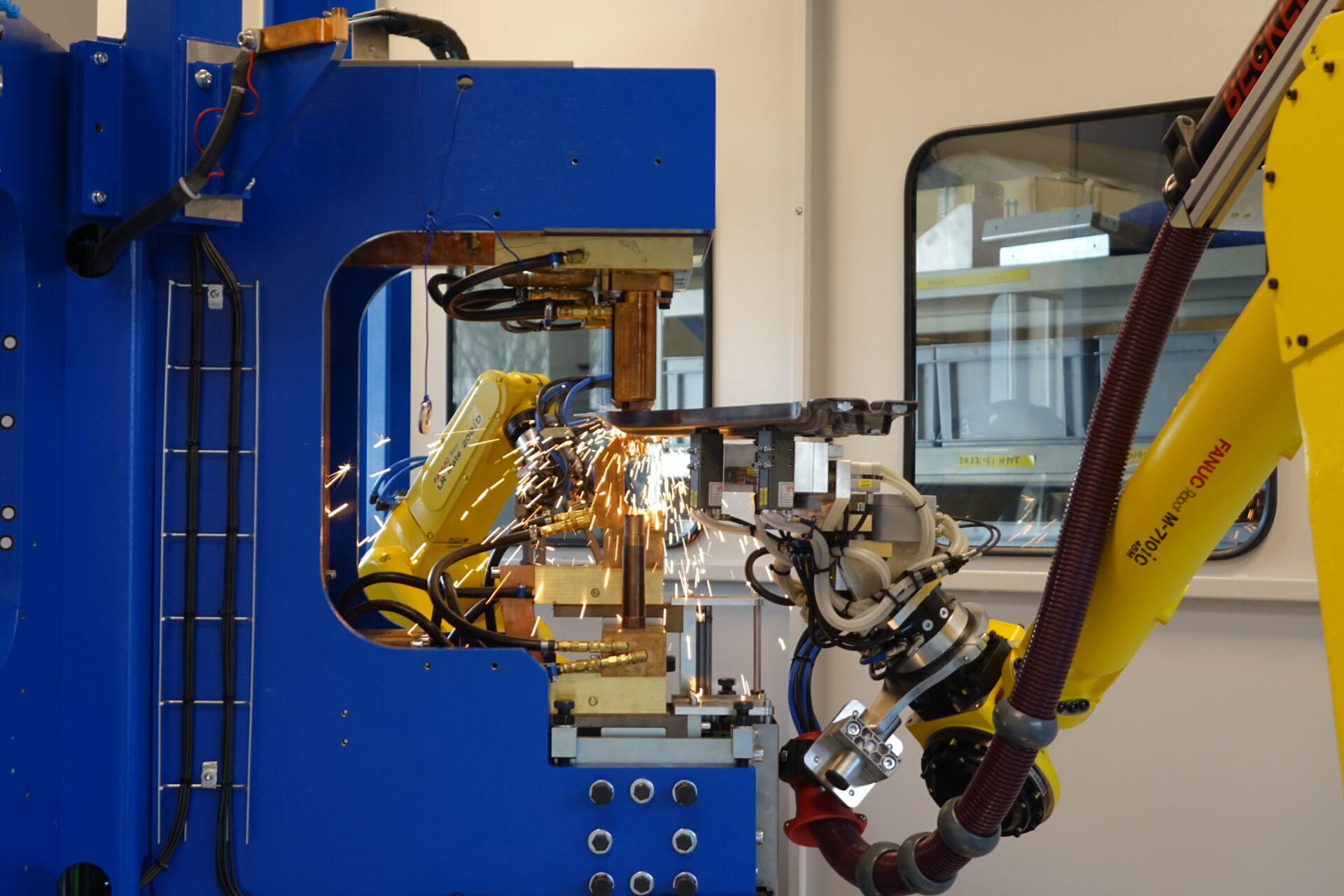

In the world of production automation, Vision technology plays a crucial role in enhancing the precision, efficiency, and quality of manufacturing processes. Vision systems, which use cameras and advanced image processing technology, have proven to be indispensable tools for picking up free-standing components, automating inspections, quality control of final products, and controlling machines.

What is vision technology?

Vision technology utilizes digital cameras, lighting systems, and powerful image processing software to capture, process, and interpret images. The results of these analyses can be used to make decisions, guide processes, or perform quality control checks.

Vision is increasingly being used in manufacturing environments and is now an essential technique in modern production facilities. In the past, production lines worked “blindly,” performing repetitive tasks. Today, these systems “see” where items are located, assess whether the offered product is correct, and can even determine if the final product was assembled correctly.

2D vision

Until recently, Vision evaluation relied primarily on 2D Vision. In this case, assessments are made based on “flat” images, often captured with monochrome cameras that only record grayscale images.

A step forward in assessment is the use of color Vision cameras. This allows the color of an object to be considered in the evaluation. This can be important when objects are the same shape but differ in characteristics. At Manders Automation, we apply this in evaluating rubber seals with the same shape but different elasticity, or in evaluating valves with the same outer contour but different switching properties.

Lighting plays a significant role in 2D Vision assessments and must be carefully selected. Various lighting methods, such as direct, back, or diffuse lighting, can highlight different aspects of an object. It’s common to use multiple types of lighting for one assessment.

3D Vision

A major development, with rapidly expanding capabilities, is the use of 3D Vision. With 3D Vision, an object is measured as a 3D object, enabling more accurate evaluations. With 3D assessment, even defects that are not noticeable to the human eye can be detected, potentially leading to quality issues.

3D Vision has the advantage of not requiring external lighting. Additionally, the stored data in 3D Vision isn’t just photographs, but actual measurement values. These measurements provide objective proof of the quality of the produced materials.

Applications of Vision technology

Vision systems are used in various manufacturing environments and processes. Some of the primary applications include:

Quality control and inspection

Vision systems are frequently used for quality control and product inspection during production. By analyzing images, these systems can detect defects, deviations, or imperfections that might otherwise go unnoticed. This ensures product quality and minimizes defective products reaching the end user or subsequent process steps.

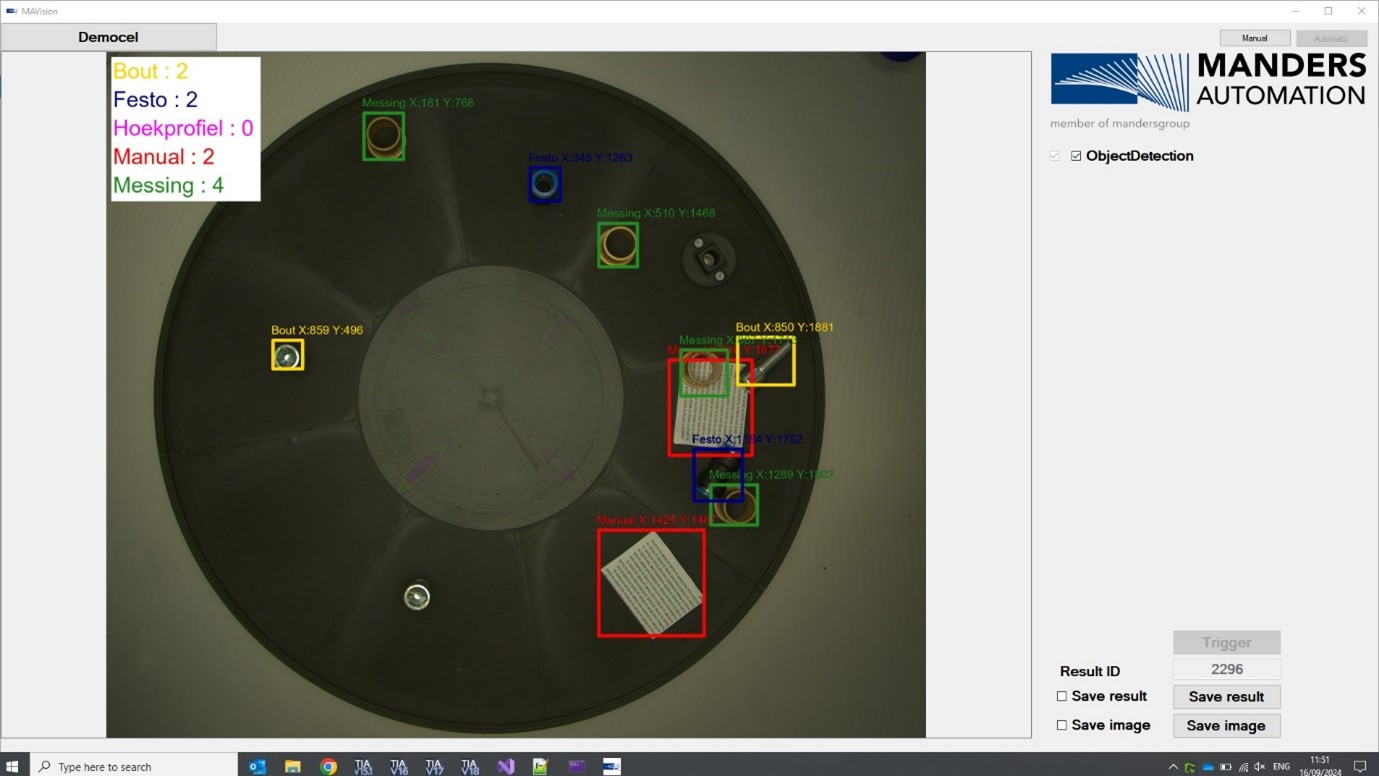

Another application is monitoring the placement of materials on product carriers. With Vision cameras, it can be ensured that the materials are placed in the correct order, in the right position, and with the correct orientation.

Positioning and guidance

In automated production and assembly lines, Vision systems can be used to determine the position and orientation of a product. Using Vision data, a robot arm can, for example, pick up the product correctly.

Another application is verifying whether parts are properly aligned, placed in the correct quantity, and whether the dimensions of the assembled final product are accurate.

Identification and tracking

Vision technology is also used for identifying and tracking products through the production process. By utilizing barcode or QR code readers, systems can automatically identify and track products, allowing for efficient and error-free production and logistics. This contributes to better inventory management and a streamlined production process.

Vision cameras can also be used to read legible text. In this case, the goal is often not process control, but quality assessment.

Assembly verification

In complex assembly processes, Vision technology helps verify whether all necessary parts are correctly installed and whether the assembly meets specifications. This prevents errors during assembly and reduces the chance of defective products that would need to be repaired or replaced later in the process.

Manders Automation has implemented systems where product quality is automatically verified, with human inspection only performed on a random sampling basis.

The use of Vision technology in production automation offers numerous benefits. Think of increased precision and consistency, improved efficiency, cost savings, enhanced flexibility, and improved evidence tracking.

Benefits of Vision technology

Increased precision and consistency

Vision systems ensure a high level of precision and consistency by automating inspections and controls that would otherwise be manual and subjective. This leads to a reduction in human errors and an increase in overall product quality.

Improved efficiency

By automating and accelerating processes using Vision technology, companies can increase production efficiency. Vision systems can perform fast and accurate inspections without breaks, contributing to a higher throughput and faster production cycles.

Cost savings

While Vision technology does require an initial investment, automating quality control and inspections often leads to cost savings in the long run. By identifying and eliminating defective products early, companies can reduce waste and repair costs.

Increased flexibility

Where Vision systems are used to pick up free-standing objects, a high degree of flexibility is introduced into the system. In principle, other products can be handled in the same way without extensive reconfiguration or new equipment. Manders has successfully applied this in installations where parts are fed onto Anyfeeders or conveyor belts.

Improved documentation

In cases where delivering a non-conforming product could lead to significant problems in subsequent processes or high costs for the supplier, stored Vision data can prove invaluable. It can demonstrate the condition of a product when it left the machine.

Advances and innovations

Vision technology continues to evolve with ongoing advancements in camera and image processing technologies. Innovations such as Artificial Intelligence (AI) and machine learning are increasingly integrated into Vision systems, making them even more powerful and versatile. These technologies enable systems to perform more complex tasks, such as recognizing patterns and making advanced decisions based on visual data. The developments in this field are moving faster than manufacturers can keep up. If you have plans involving Vision technology, we are happy to help you find the best available solutions.

Conclusion

Vision technology plays a key role in modern production automation by providing accurate, efficient, and reliable solutions for inspection, positioning, identification, and tracking. The benefits of Vision systems include increased precision, improved efficiency, and cost savings, which contribute to higher product quality and optimized production processes.

At Manders Automation, we specialize in implementing Vision technology that seamlessly integrates with your production processes. If you want to learn more about how Vision systems can improve your production or need advice on the best solutions for your needs, feel free to contact us. We are here to help you leverage the latest technologies for efficient and successful production.