Automotive

If you work in automotive, you know how important speed, precision and reliability are. But that also brings challenges. Products are becoming increasingly complex and requirements ever higher, while the pressure to keep costs down continues to rise. And then there is the scarcity of qualified personnel for critical tasks such as welding, gluing and assembling parts. It is not just a question of working faster, but also of ensuring the safety of your team and the quality of the final product. These challenges require smart solutions that are often difficult to achieve with traditional processes.

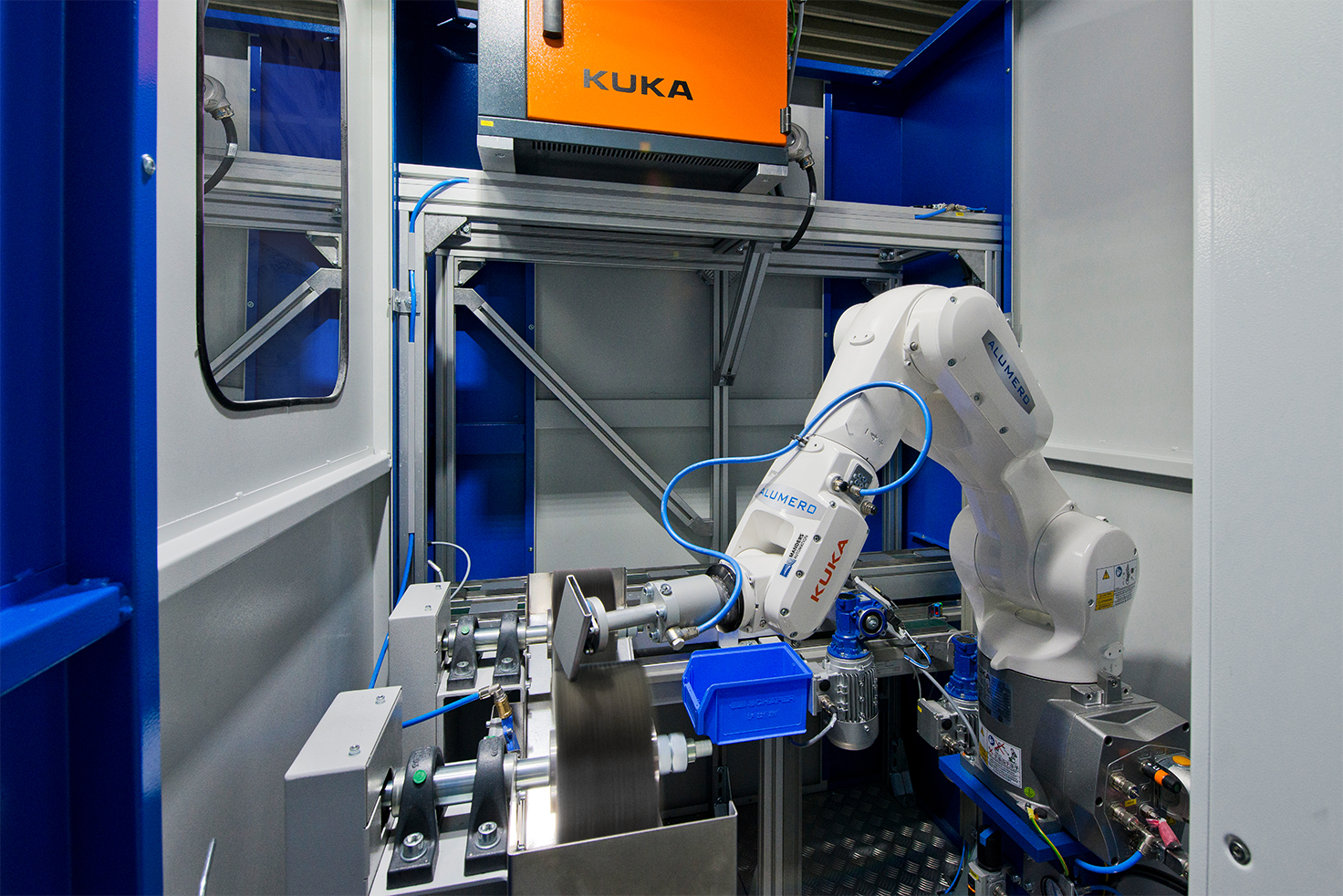

Automation enables more efficient, consistent and safer production. Think robots that perform precise welding, or automated systems that apply the right amount of glue at the right time. For the automotive industry, this means you can switch faster between different models and materials, from steel to aluminium or plastic, without sacrificing precision or quality. Moreover, vision technologies help you detect errors instantly and adjust processes where necessary, so you always know that every part meets the highest quality standards.

With 40 years of experience in customised automation solutions, we ensure that your production line runs reliably, production costs decrease and your team stays safe. From complex assembly lines to precise dosing and gluing processes, we help you maximise the benefits of automation.